E3AS Series changes the “way of using” reflective photoelectric sensors

Production lines have become more advanced and complex, and skilled production workers are hard to come by. In order to increase equipment design flexibility and reduce sensor installation time, there is a growing need for reflective photoelectric sensors that require no receivers or reflectors. OMRON’s E3AS Series offers new ways of using reflective photoelectric sensors to reduce line commissioning time and increase uptime.

Different ways of using OMRON E3AS Series

- Multi-lane conveyor lines of targets with curved surface

- Complex-shaped, colored, patterned or glossy targets

- Long-distance sensing on converging and diverging lines

- Inclined and close mounting

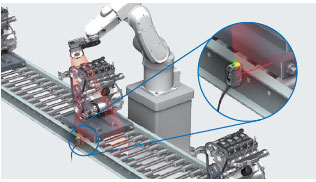

E3AS-HL for multi-lane conveyor lines of targets with curved surface

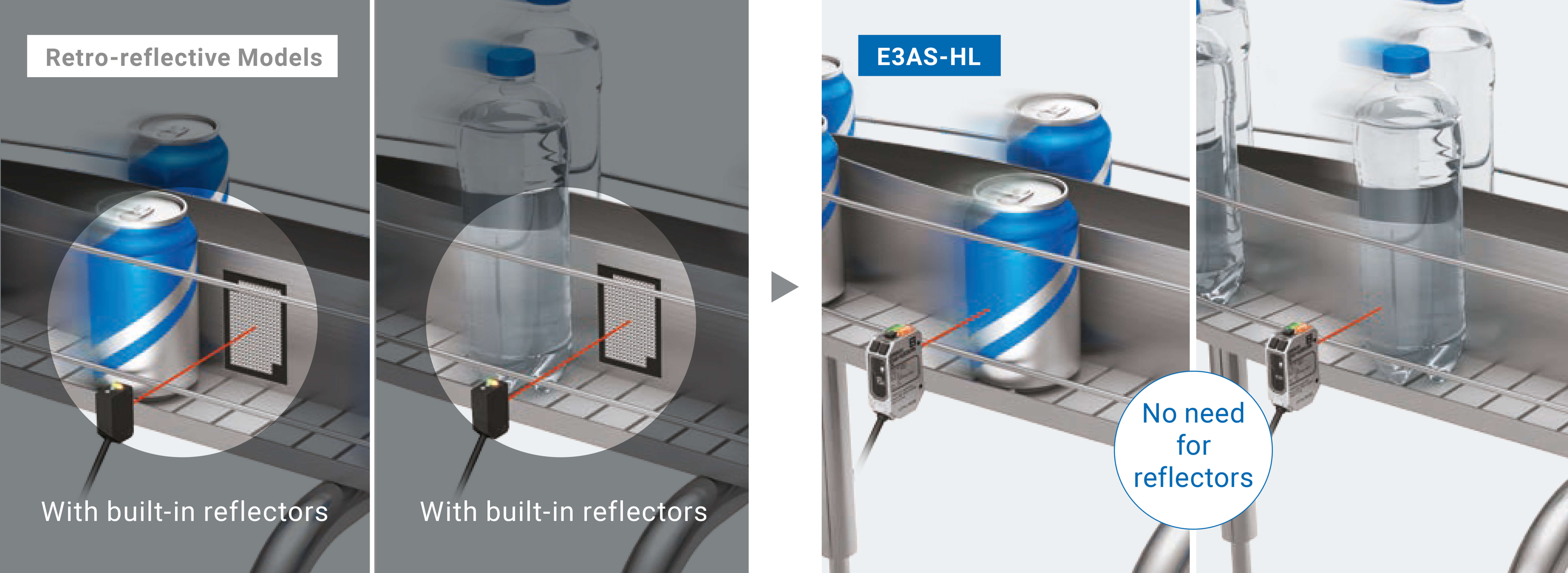

Stably detects cans and plastic bottles without reflectors

Left image: Retro-reflective sensors are used to detect poorly reflective curved surfaces of cans and transparent plastic bottles, but securing installation space for reflectors on multi-lane conveyor lines is difficult.

Right image: The E3AS-HL Sensor, a reflective model capable of detecting the slightest change in the incident light level or distance, can stably detect cans and plastic bottles without reflectors.

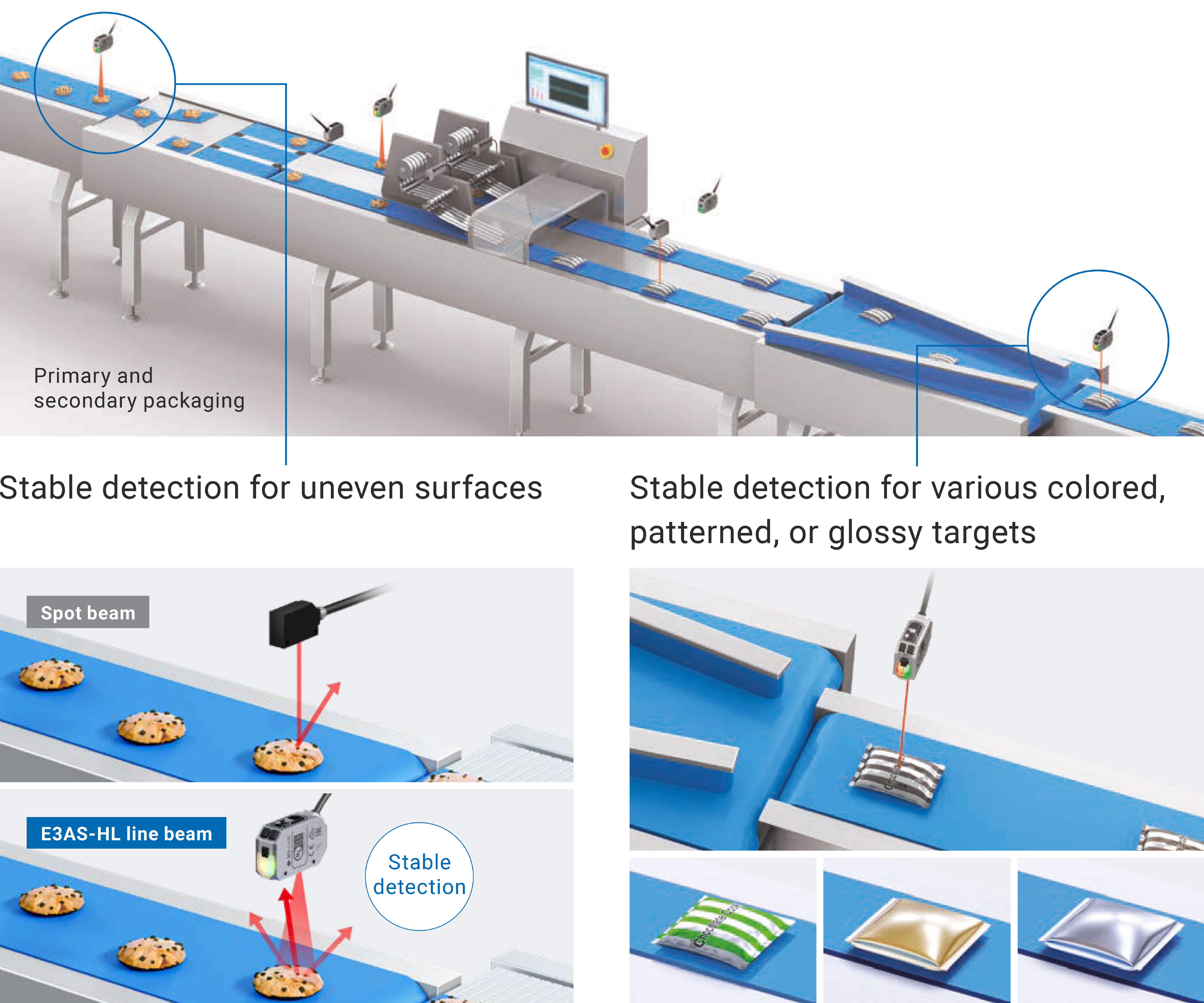

E3AS-HL for complex-shaped, colored, patterned or glossy targets

Left image: With spot beam, detection is unstable since the reflected light does not reach the sensor depending on the profile of the target surface. With the line beam of the E3AS-HL Sensor, detection is less affected by the profile of the surface since the reflected light reaches the sensor from any part of the surface.

Right image: Detection is prone to be unstable because color, pattern or reflectivity affects the sensing distance. The E3AS-HL Sensor is less likely to be affected by them, providing stable detection even when packaging materials change.

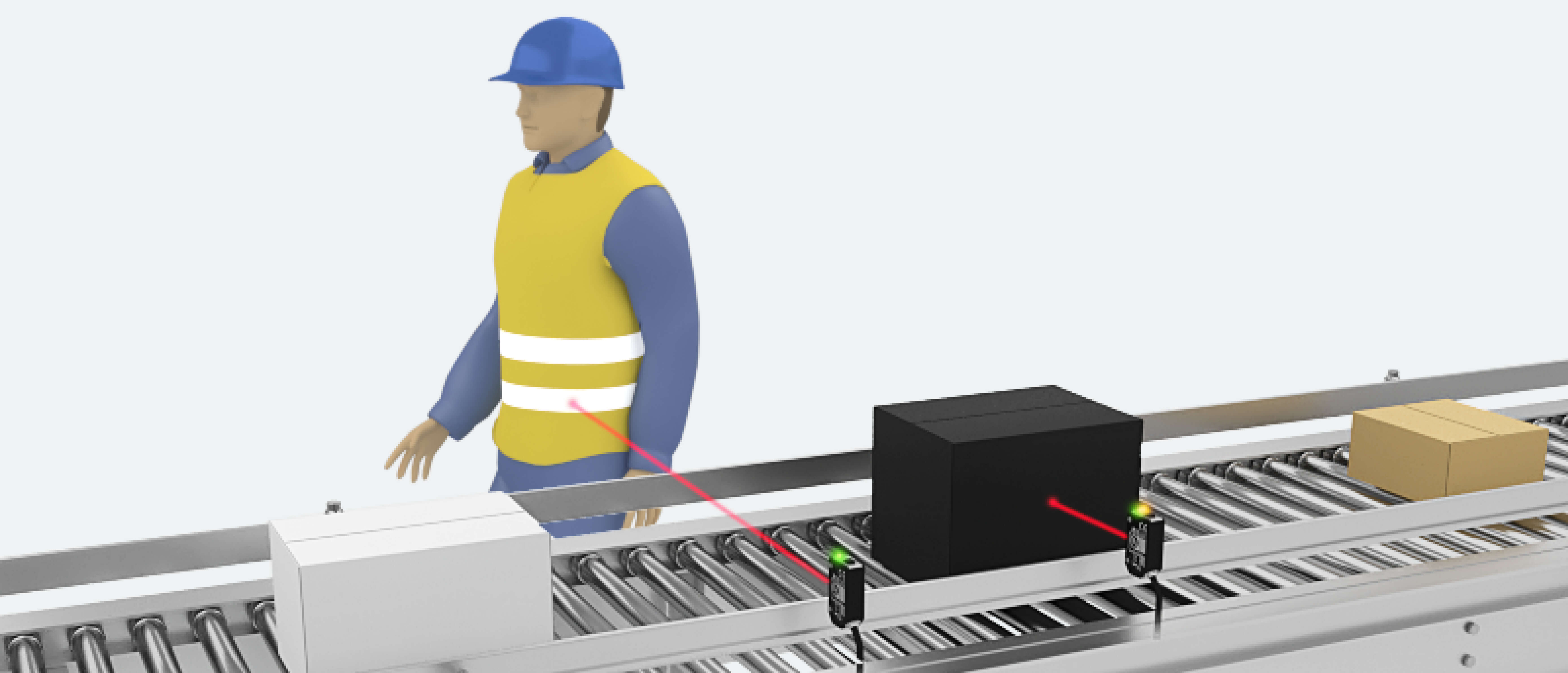

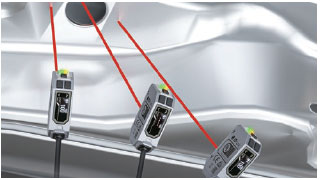

E3AS-F for long-distance sensing on converging and diverging lines

No reflector is required to design long-distance sensing unaffected by color or material of targets

Although retro-reflective sensors are used for long-distance sensing in converging and diverging lines, it is difficult to find installation space for reflectors.

The E3AS-HL Sensor, a reflective model with long sensing distance, does not require reflectors. Moreover, it is less likely to be affected by color even from long distances.

TOF method enables the detection of various workpieces on the conveyor line

With conventional photoelectric sensors, prior evaluation was required for each workpiece to be detected. E3AS-F Sensors detect workpieces varying in colors and materials by the set distance. This helps reduce evaluation and adjustment time. Also, they do not detect workers working near the line by mistake.

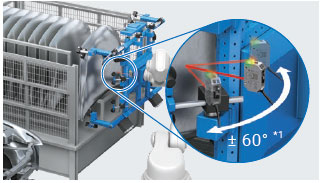

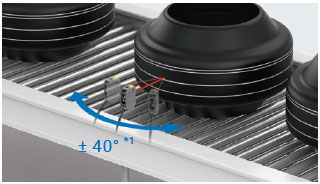

E3AS-HL for inclined and close mounting

Install regardless of workpiece shape and angle

Curved surfaces of metal workpieces tend to affect detection, and it is time-consuming to design the mounting angle. E3AS-HL Sensors can be mounted at a wide-angle, making setup eas

Curved surfaces of low-reflective workpieces tend to affect detection, and it is time-consuming to design the mounting angle. E3AS-HL Sensors can be mounted at a wide angle, making setup easy.

Install in confined spaces or near lights

Interference with other sensors must be considered during design. E3AS-HL Sensors prevent mutual interference between up to 4 sensors, allowing close installation for applications like item identification from hole positions.

Effects of lights for cameras and sunlight must be considered during design. E3AS-HL Sensors can be operated under ambient illumination of 20,000 lx, which reaches the best in class level *2. This allows you to install the sensors in the vicinity of lights.

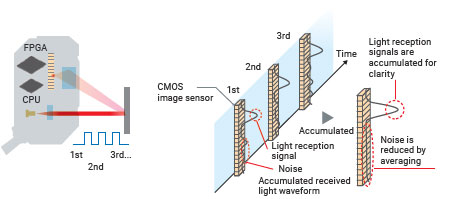

Sensing algorithm detects minimal reflected light from curved surface [PATENTED]

The E3AS-HL Sensor is the industry-first laser Class 1 CMOS laser sensor that comes equipped with an FPGA.

It performs high-speed sampling of received light waveforms at 10,000 times per second and OMRON’s unique accumulation processing, significantly increasing its sensitivity. It amplifies the slightest amount of light to reliably detect workpieces with glossy surfaces, complex shaped workpieces, black rubber, or other workpieces from which it is difficult to receive reflected light

Features of OMRON E3AS Series

1. Antifouling coating on sensing surface

Ensures stable operation even in harsh environments

When a sensor malfunction or breakage due to the environment causes a line stoppage during mass production, it can take a long time to restart. With the protected sensing surface, the E3AS Series helps minimize line downtime and maximize uptime.

Reduces false detection and cleaning frequency [PATENT PENDING]

A dirty sensing surface can cause false detection due to the principle of photoelectric sensors. The E3AS Series has an industry-first antifouling coating on the sensing surface which prevents oil mist and dust from sticking to the sensing surface and keeps the lens from fogging as well. This reduces false detection and sensing surface cleaning frequency.

Prevents contamination on the sensing surface

Dirty sensing surface can cause false detection due to the principle of photoelectric sensors. E3AS Series with the antifouling coating on the sensing surface, which is the industry’s first, prevents water droplets, oil, and dust from sticking to the sensing surface, and keeps the lens from fogging as well. Therefore, the coating prevents contamination on the sensing surface in environments where oil or dust scatters, or steam generates. False detection and cleaning frequency are also reduced.

Air blow unit enhances the effectiveness of antifouling coating [PATENTED]

Using an air blow unit greatly reduces the frequency of false detections since it prevents the sensing surface of sensors installed in confined, difficult to clean locations from becoming contaminated. It can be mounted to any photoelectric sensor with a 25.4 mm mounting hole pitch as well as the E3AS Sensors.

2. Front protection cover reduces sensor failures

Welding spatter on the sensing surface or collision during operation can cause a sensor failure, and the sensor sometimes need to be replaced. Mounting the front protection cover prevents sensor failures. When any problems occur with the front protection cover, just replace it. There is no need to replace the sensor and rewire it.

Unique case design reduces the frequency of replacements caused by failure

The sensor case is made of stainless steel (SUS316L). OMRON’s unique laser welding technology for different materials enhances the sealing and adhesion between the stainless steel and resin. The laser welding technology for metals are used to weld the case and cover of the E3AS-F Sensor for secure sealing and adhesion between the stainless steel.

3. Laser welding technology

Laser welding technologies for different materials/metals for increased environmental resistance

The sensor case is made of stainless steel (SUS316L). Omron’s two unique technologies, laser welding technology for different materials and laser welding technology for metals, enhanced the sealing and adhesion between stainless steel and resin.

Laser welding technology for different materials

It is a technology to weld different materials, resin and metal, using laser beams. Small holes are bored into the metal case, then melt the resin part by laser. The melted resin fills the holes for secure sealing and adhesion.

Laser welding technology for metals

The metal case and cover are welded by a laser beam to seal the gaps. This provides higher airtightness compared to adhesives, keeping out water, oil and other substances to reduce failures.

4. Aesthetic of Sensor

Flexible installation saves design time

Sensor space limitations make equipment design and retrofit work complicated, resulting in time-consuming work. The E3AS Series can be installed in challenging locations, which reduces design and commissioning time.

OLED display and teaching enable easy, quick, and optimal setting

E3AS Sensors allow virtually anyone to set optimal settings on the easy-to-read OLED display using the teaching method. Moreover, easy-to-standardize operability makes remote instructions simple.

Easy-to-read, easy-to-understand OLED display [CMOS E3AS-HL]

Displaying the threshold level and detected value on the same screen makes threshold level setting easy. In addition, wide viewing angle and display inverting allow on-site workers to easily see the display.

Single teach button prevents inconsistent settings

Easily and consistently set the optimal threshold level using the teach button.

5. Fast and easy setup also when setting a large number of sensors

Sensitivity adjustment using the conventional adjuster method requires experience, finesse as well as time since the threshold level must be adjusted one unit at a time.

With the E3AS Series, just press the teach button to automatically set the threshold level, enabling fast and easy setting.

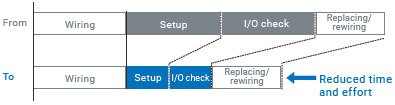

Line commissioning and maintenance with less people in less time with IO-Link

With IO-Link, reduce commissioning time by batch-setting the sensors and cut troubleshooting time during mass production by utilizing field data.

Reduce commissioning time by batch-writing settings from IO-Link device configuration tool

Setting information can be batch-written to thousands of sensors on a line, effectively reducing commissioning time and inconsistent settings.

Predictive monitoring and quick recovery by checking and monitoring sensor data

The monitor shows light intensity decrease due to sensing surface contamination or other reason, allowing users to take proactive actions to prevent potential false detections. This reduces the frequency of unexpected failures.

Look inside the E3AS photoelectric sensor: 3D blowout video

OMRON E3AS Photoelectric Sensors | Flexible to design for Food Industry without reflectors.

Interested to find out more about Omron E3AS Photoelectric Sensors? Feel free to contact us!